Opis

Vrsta izdelka: kvadratna cev iz nerjavečega jekla, kvadratna cev iz mehkega jekla, kvadratna pocinkana jeklena cev

Uporaba: Pogosto se uporablja v pohištvu, notranji dekoraciji, strukturi

Velikost: OD: 10 * 10-1000 * 1000 mm

Standard cevi:

Nerjaveče jeklo: ASTM A249 - A269 - A312 - A358 - A409 - A554 - A778 - A789 - A790

Blago jeklo: ASTM A500, ASTM A53, DIN EN 10210, DIN EN 10219, JIS G3466, BS1387, BS6323

S235JR, S355JR, St37, St37-2, St52, SS400, STK500

Površina: črno gola, lahko galvanizirana, naoljena, barvana, praškasta.

Pakiranje: vodotesna plastična vrečka, sveženj s trakom

Specifikacija

Velikosti kvadratnih cevi

|

Velikost (mm) |

Debelina stene (mm) |

Velikost (mm) |

Debelina stene (mm) |

|

20*20 |

1.2 |

70*70 60*80 100*40 |

1.8 |

|

1.3 |

2 |

||

|

1.4-1.5 |

2.2 |

||

|

1.7 |

2.3 |

||

|

1.8 |

2.5-4.0 |

||

|

2 |

4.5-5.0 |

||

|

2.2 |

5.5-5.75 |

||

|

2.3 |

75*75 60*90 100*50 |

1.8 |

|

|

2.5-2.75 |

2 |

||

|

25*25 20*30 |

1.2 |

2.2 |

|

|

1.3 |

2.3 |

||

|

1.5 |

2.5-4.0 |

||

|

1.7 |

4.5-5.0 |

||

|

1.8 |

5.5-5.75 |

||

|

2 |

80*80 100*60 100*80 120*60 |

2 |

|

|

2.3-2.3 |

2.2 |

||

|

2.5-3.0 |

2.3 |

||

|

30*30 30*40 25*40 20*40 |

1 |

2.5-4.0 |

|

|

1.2 |

4.5-5.0 |

||

|

1.3 |

5.5-5.75 |

||

|

1.5 |

7.5-7.75 |

||

|

1.7 |

100*100 120*80 |

2 |

|

|

1.8 |

2.2 |

||

|

2 |

2.3 |

||

|

2.2 |

2.5-5.0 |

||

|

2.3 |

5.5-5.75 |

||

|

2.5*2.75 |

7.5-7.75 |

||

|

3 |

120*120 140*80 150*100 160*80 |

2.5 |

|

|

40*40 30*50 25*50 |

1.2 |

2.75 |

|

|

1.3 |

3 |

||

|

1.4-1.5 |

3.25-5.0 |

||

|

1.7 |

5.5-7.0 |

||

|

1.8 |

7.5-7.75 |

||

|

2 |

140*140 150*150 200*100 |

3.5-4.0 |

|

|

2.2-2.3 |

4.5-5.0 |

||

|

2.5-4.0 |

5.25-7.0 |

||

|

50*50 60*40 30*60 40*50 |

1.5 |

7.5-7.75 |

|

|

1.7 |

160*160 180*180 |

3 |

|

|

1.8 |

3.5 |

||

|

2 |

3.75 |

||

|

2.2 |

4.0-5.0 |

||

|

2.3 |

5.25-5.75 |

||

|

2.5*-4.0 |

7.5-7.75 |

||

|

4.25-5.0 |

60*60 40*80 75*75 50*70 50*80 |

2.3 |

|

|

60*60 40*80 75*45 50*70 50*80 |

1.5 |

2.5-4.0 |

|

|

1.7 |

4.25-5.0 |

||

|

1.8 |

5.5-5.75 |

||

|

2 |

/ |

||

|

2.2-2.3 |

/ |

Standardno

Kemična sestava materiala

| Ocena | element | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

| V skladu z EN10027/1 | V skladu z EN10027/2 | C% max (Norminalna WT (mm) | Si % maks | Mn % maks | P % maks | S% maks | N% maks | |

| in IC 10 | Manjše ali enako 40 | |||||||

| S235JRH | 1.0039 | 0.17 | 0.20 | - | 1.40 | 0.045 | 0.045 | 0.009 |

| S275JOH | 1.0149 | 0.20 | 0.22 | - | 1.50 | 0.040 | 0.040 | 0.009 |

| S275J2H | 1.0138 | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | - |

| S355JOH | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0.040 | 0.040 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | - |

Mehanske lastnosti materiala

| Ocena | Moč tečenja | Natezna trdnost | Raztezek |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norma | Moč tečenja | Natezna trdnost | Min.elogacija | Min.odstotne lastnosti | ||||||||

|

V skladu z EN10027/1 in IC 10

|

V skladu z EN10027/2 | Normalna WTmm | Normalna WTmm | Longit. | Križ | Stopnja preskusne temperature | Povprečna minimalna vrednost vpliva | |||||

| Manjše ali enako 16 | >6 | >40 | <3 | Manjše ali enako 3 Manjše ali enako 65 | Normalna WTmm | |||||||

| Manjše ali enako 65 | Manjše ali enako 65 | Manjše ali enako 40 | >40 | >40 | Manjše ali enako 65 | |||||||

| Manjše ali enako 65 | Manjše ali enako 40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Enakovredne specifikacije

|

EN 10210-1 |

NF A 49501 NF A 35501 |

DIN 17100 DIN 17123/4/5 |

BS 4360 |

UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | – | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | – | St E 285 N | – | – |

| S275NLH | – | TSt E 285 N | 43 EE | – |

| S355NH | E 355 R | St E 355 N | – | – |

| S355NLH | – | TSt E 355 N | 50 EE | – |

| S460NH | E 460 R | St E 460 N | – | – |

| S460NLH | – | TSt E 460 N | 55 EE | – |

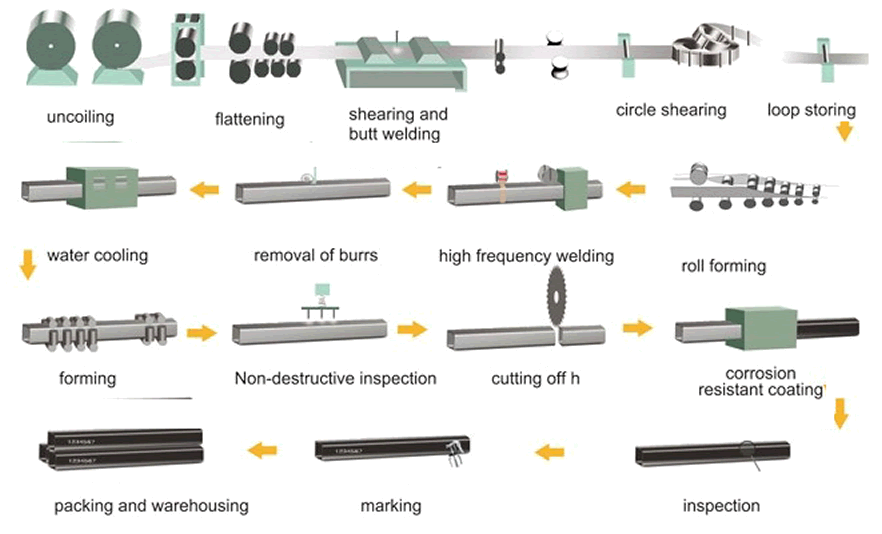

Proces